TRUSSCORE PVC LINER IS GOING IN THE SOUTHGATE HONEY SHED BUILD | JCB AND SONS

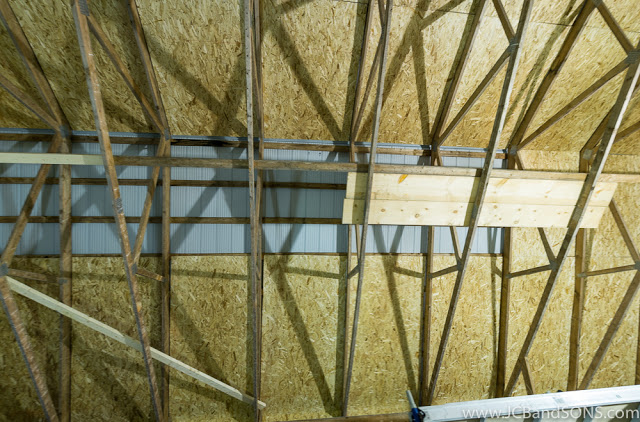

PVC Liner is going in the Southgate Honey Shed Build | JCB & SONS. We installed 1/4"

board inside of the original pole shed prior to the polyurethane spray foam. This allowed an air space between the foam and the roof steel, and also prevents the foam from bonding to the roof steel in the event it ever had to be replaced.

Both the original pole shed and the new addition received new steel trims and wall steel to modernize the building and make it all match.

The roof of the original building was spray foamed to allow the open webbing of the trusses to stay exposed and allow more storage.

The walls of the addition were spray foamed to ensure an air tight seal on the extraction room walls to make it easy to heat and keep out any bees during the honey extraction process.

from Durham did a super clean install on these 50,000 BTU Propane heaters from

. Two heaters where installed on separate thermostats to allow the heating to be controlled in the extraction room, and shop/storage areas separately

PVC Liner is being installed on the ceiling and walls of the extraction room. Its a food grade liner, which is smooth and easy to clean, and white keeping the room bright. Also this liner is manufactured in Palmerston, ON allowing us to support local business.