TOWNSEND LAKE WEST GREY ONTARIO COVERED PORCH BUILD | JCB AND SONS

We built this new covered porch on this cottage to allow access from the front of the cottage to the back deck overlooking Townsend Lake. The foundation piers were created using BF20 Bigfoots with 10" quick-tubes installed 4'-0" below grade to ensure adequate frost protection.

The piers were filled with cement and 2 pieces of 15mm rebar to make strong supports as well as carport saddles were installed to anchor the new structure to the base.

Deck building is a form of trim carpentry so all corners are mitered even on the framing.

Galvanized joist hanger brackets were used with galvanized joist hanger nails to get flush beams keeping the framing off of the ground even at the lowest end.

Deck flashing was used on the top of all the framing to ensure the top of the framing will not rot.

Kreg Jigs hidden deck fastner system was used to hide all of the screws used to fasten the decking.

All of the roof framing stayed exposed so the rafters and strapping were all rounded over and a coat of Sikkens Stain was used to weather proof it prior to installing.

Steel roofing was used on the 2 ends and polycarbonate x-ligh was used to keep the porch roof nice and bright. Strapping was ran on 12" centres to give lots of support to the x-light.

The wooden structural beam was clad in pine barn board and finished with a coat of Sikkens Cedar Stain.

We installed new vented soffit on the ends to tie neatly into the home and clad all the fascia boards in aluminum fascia we custom bent on site.

We installed 2"x4" rails with a 2"x6" handrail which received a nice big round over to create the railings for the porch. The homeowner has plans for his own spindles and is looking after that himself.

DURHAM MOBILE HOMES & PARK LTD. GETS NEW NORTHLANDER INDUSTRIES MANUFACTURED HOMES | JCB AND SONS

Durham Mobile Homes & Park Ltd gets new Nothlander Industries Manufactured Homes | JCB & SONS. We have been spending sometime at the Durham Mobile Home Park in West Grey setting two brand new Mobile Homes from Northlander Industries.

First the sites at the park were prepared for the new mobile homes with brand new footings. This included new piers set on 24" Big Foots 4'-0" below grade to ensure proper frost protection, which is than covered with a wide cement runner to protect the piers during the installation of the new homes.

15mm rebar is installed in every pier as well as in the cement runner the wheels ride on while the home is being backed into place.

The new homes are carefully guided onto the new footings, ready to have the axles removed and set on cement blocks using a large tractor.

These new homes from Northlander Industries are both 14'-0" wide x 66'-0" long and are available up to 72'-0" long. The factory also offers beautiful side entrance additions, as well as many customization options.

Once the homes are sitting on their new solid cement blocks a pressure treated frame is assembled to hold the new vinyl skirting. Than the new vinyl skirting comes right from Northlander to insure a 100% perfect colour match to the new home.

We also built new Pressure Treated Decks with maintenance free aluminum railings. This particular home also received a ramp for easy access for the client.

The sites were finished off with all the disturbed areas getting new topsoil levelled off and fresh grass seed for a beautiful future lawn.

WEST GREY ONTARIO MASTER BEDROOM WALK IN CLOSET BUILD | JCB AND SONS

West Grey Ontario Master Bedroom Walk In Closet Build | JCB & SONS. This 1978 home needed a larger MasterBedroom, we removed a dividing wall between two bedrooms, removed textured ceilings and finished out the drywall with a level 5 skim coat to leave perfectly smooth ceilings. Installed new 3/4" Maple Hardwood Flooring and Completely overhauled the closets with completely custom build cabinetry, wardrobe, builtins, drawers, and custom made mirrored doors for the closets. We also had a new high efficiency furnace system installed in this home with new duct work and an HRV to keep this bedroom as well as the whole house the perfect temperature year round.

All of the Cabinets were full 3/4" Plycore Maple Veneer Construction.

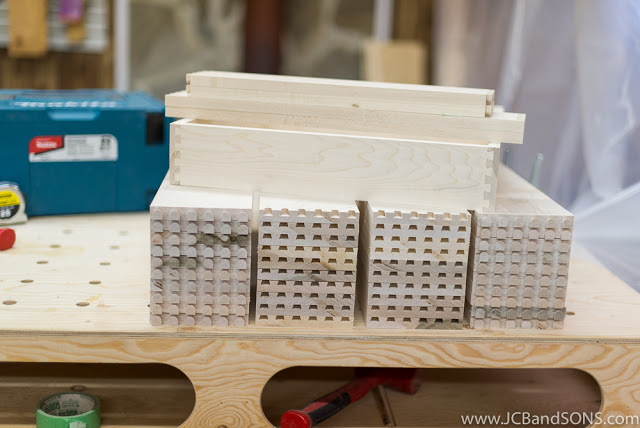

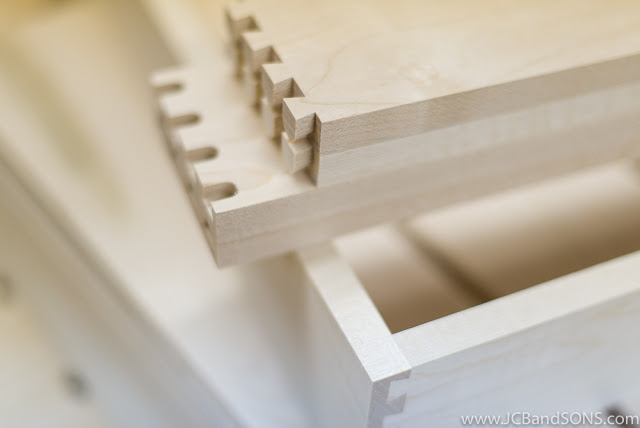

The face frames were all built using a very traditional mortise and tenon joint. Making a very durable quality connection of the styles and rails.

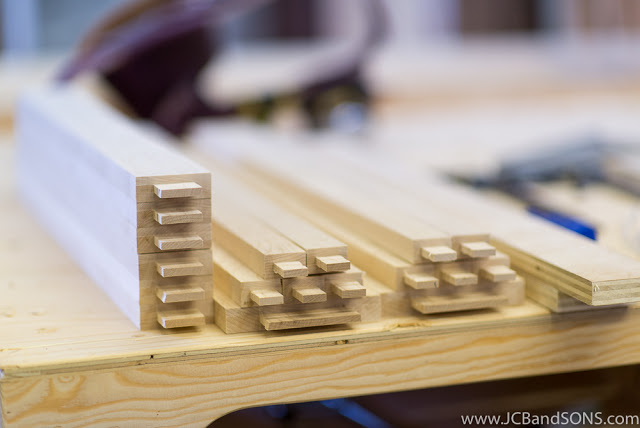

These are the Tenons that will make the connection with all the mortises.

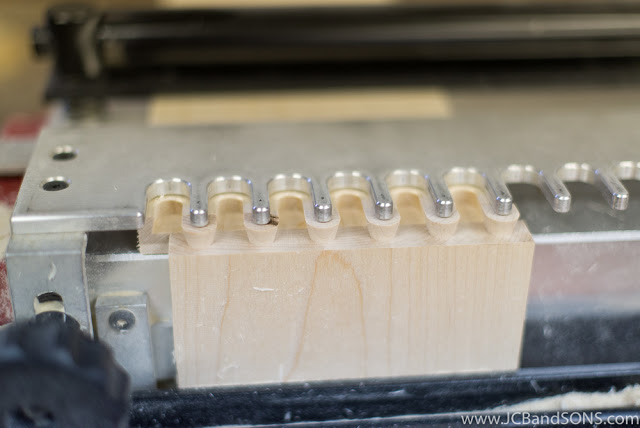

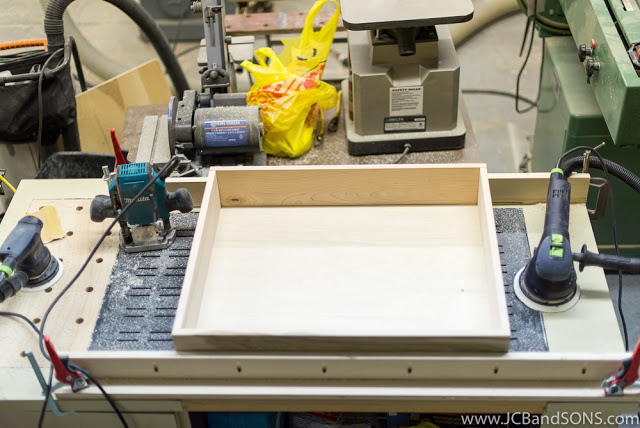

All of the drawer boxes were made using soft maple and blind dovetails cut onsite at our shop.

We used all solid Hard Maple for the face frames and classic styled raised panel doors which were also all milled and built in our shop.

Milling the styles and rails on our spindle molder.

The completed cabinets where than sprayed with 3 coats of Lacquer to provide a very high quality durable finish.

These 8' Maple mirrored doors were installed on high quality Johnson hardware and glide effortlessly as sliding doors should.

We also built a completely maple wardrobe to be part of all the cabinets and create some fantastic hanging storage with adjustable wire rack shelving.

All of the shelving received solid maple nosing verses the typical edgebanding you see on cabinet shelving.

The drywall beam used to support the ceiling after removing a dividing wall was a great place to use some Trim Tex Step-A-Bull Corner beads for a great detail.

The closets also received Maple built ins in the closets on top of the adjustable wire rack shelving and they also received full face frames.